AGRIST AGRIST Interview: Developing Agriculture Technology to Support the Aging Farmers of Japan

In an interview with Mr. Nagata, Head of Development at AGRIST Corporation, we discussed their creation of an automatic green pepper harvester aimed at aiding Japanese agriculture and aging farmers. Mr. Nagata elaborated on the steps taken to ensure maximum accuracy in the AI camera during the harvester's development.

AGRIST, changing the world of agriculture. Five years since its founding, AGRIST is experiencing exponential growth, propelled by its in-house development of the automatic harvester.

Can you tell us an overview of AGRIST's business?

"We specialize in developing automatic harvesting robots for agriculture. Our motivation stems from the pressing need to support aging farmers and sustain agriculture. In Japan, the average age of individuals involved in agriculture hovers around 70. Even when recruiting part-time workers for harvesting, many are in their 70s and 80s. If the current trend persists, there may be a significant shortage of agricultural workers within the next decade."

Mr. Nagata of AGRIST.

The aging of the farming population is a major issue for Japanese society, isn't it? Is that why the company was created?

"When our company was founded, young green pepper farmers in Miyazaki regularly organized study sessions, inviting lecturers to share insights once a month. Our founder, Mr. Saito, was an attendee at these meetings. It was during one of these sessions that the issue of harvesting emerged as a significant concern. Despite the farmers' adoption of advanced technology to increase pepper yields, the absence of labor for harvesting posed a critical challenge. This resulted in missed opportunities as peppers either grew too large to be marketable or ripened to red and fell off the plants, leading to financial losses.

Inspired by this problem, we created the 'green pepper robot' as a solution to mitigate waste. People often ask why we specifically targeted green peppers. However, the decision was already made— we decided on green peppers then made a robot specifically for it! (laughs)"

Thank you very much. Green peppers are the main agricultural crop in Shintomi Town (Miyazaki Prefecture), where the company was founded, aren't they?

“Yes, it is. Ibaraki and Miyazaki prefectures account for the first and second largest shipments of green peppers.

One of the key features of the automatic harvester we're developing is its 'hanging type' design. In this configuration, a wire is stretched across the greenhouse, allowing the robot to be suspended and move along the wire. Ground conditions and the spaces between rows are often challenging, characterized by the passage of water and warm air, uneven terrain with soil bumps, and muddy patches. After considering inputs from farmers, we opted for the current system of suspending the robot by wire and enabling it to traverse through the air."

Impressive! Do you harvest with this arm?

“Yes, we call it the "harvesting hand," the robot harvests green peppers with this.”

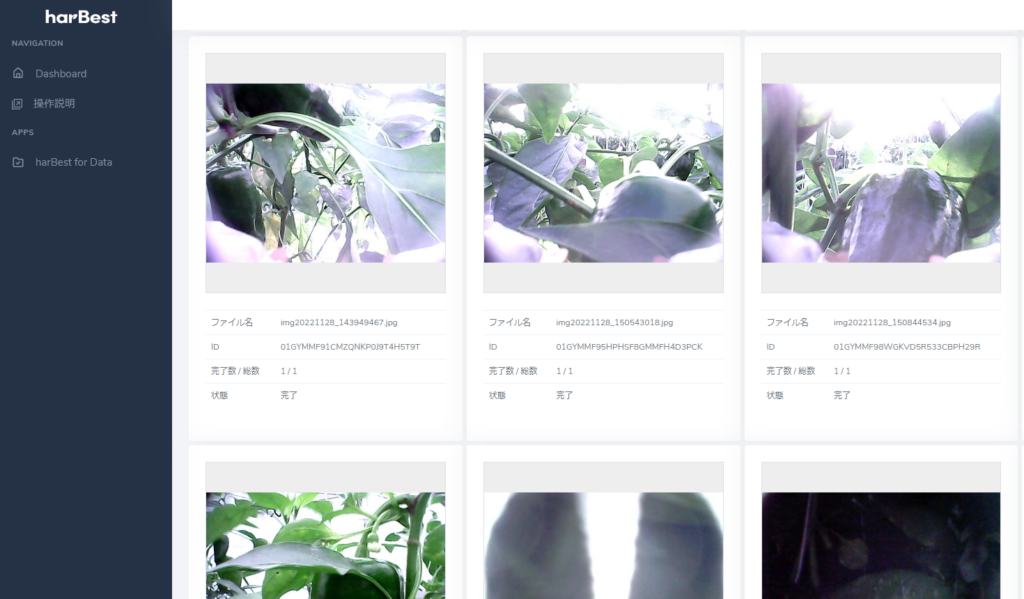

“The camera mounted on the robot's hand identifies the "position" and "size" of the peppers from a distance and approaches them accordingly. Using the annotated learning data provided by harBest, the robot makes informed decisions. If the pepper is deemed harvestable, the robot will go on and harvest it. We categorize peppers into the following groups: (1) harvestable peppers, (2) peppers obstructed by branches, (3) peppers concealed by leaves, (4) peppers of inappropriate size, and (5) other exceptions. The robot selectively harvests only those peppers deemed suitable while avoiding those deemed unsuitable.”

The challenge of classification tasks for a large volume of images is where harBest came into play.

Were there a lot of challenges in the early stages of development?

"It was quite a challenge (laughs). Initially, the robot struggled to harvest green peppers efficiently. It wasn't until around March 2022, if I recall correctly, that we started seeing significant progress in pepper picking. The robot would approach the peppers, but it would halt just before harvesting them. Initially, even spotting the green peppers proved to be extremely difficult. And even when we managed to do so, achieving precision in harvesting was a challenge.

Through some creative problem-solving, we eventually succeeded in harvesting the peppers. However, a new issue arose; we inadvertently began cutting surrounding branches as well. Since peppers bear fruit all over the plant, cutting peppers close to branches often resulted in cutting the branches themselves. Trimming the branches meant losing potential earnings from future pepper growth."

That's a big loss.

"It really is, and even just one failure made a big impact. So, to fix the problems we used your local information annotation data, the accuracy improved, and here we are today."

How did you find out about our company?

"We were introduced to APTO by a friend's company. I thought "annotation by crowdworkers" sounded interesting. I wasn’t expecting a lot, but I was told that APTO would also perform quality control of the data, so I decided to give harBest a try."

How was your experience with our service?

"To be honest, the quality of the data was much higher than we had expected. It was also good that the work itself was done very fast. When I think back on the time we spent on frequent meetings with APTO, creating the manual through trial and error, I have fond memories of that time (laughs)."

Creating a manual for the crowdworkers was challenging, wasn't it?

"Some of the terms used for our crops are not common, and many people are unfamiliar with words such as "peduncle," so I think it was a challenge when we were brainstorming on how to best convey the annotation manual to the workers that have little knowledge of agriculture."

Thank you for your feedback. We will continue to develop our platform to make it easier to use. Finally, what are AGRIST's future goals?

"Right now, we are starting to develop a cucumber harvesting robot. However, as we found out after trying it, it is extremely difficult to develop a general-purpose robot that can harvest any kind of crop, and it can’t be used if the target crop is slightly different. The green pepper robot will be completed soon. We cannot use it for another crop as it is, but if you give us some time, I think we can expand the variety of crops in a short time by utilizing the knowledge we gained from the development of the bell pepper robot."

Thank you very much for your time, Mr. Nagata!

harBest will continue to make efforts to contribute to solving agricultural issues!

関連事例

-

LLM development at the highest level in Japan. What are the challenges faced by a research team devoted to improving accuracy?

Institute of Physical and Chemical Research(RIKEN)

- IT/Internet

- R&D

- Annotation

- Data collection

- Data Management

- Experienced

-

Search real estate all over the world at once using satellite data. What kind of future will “WHERE” make possible?

Penetrator

- IT/Internet

- real estate

- Annotation

- Data collection

- Data Management

- Experienced

-

“I started developing AI behind the scenes at a television station. Now I want to spread this throughout the company”

FUJIMIC, Inc.

- Annotation

- Data Management/Labeling

- IT/Internet

- Annotation

- Data collection

- Experienced

-

Achieve efficient form management by utilizing AI data. The secret to the success of ‘PATPOST’

ORIX Corporation

- Annotation

- Data Management/Labeling

- IT/Internet

- Annotation

- Data collection

- Experienced

-

Streamlining Development After Successful Outsourcing of High-Volume Annotation Work

The Ricoh Company, Ltd

- AI Development (Experienced)

- Annotation

- Data Management/Labeling

- IT/Internet

- Annotation

- Experienced

-

How Leading AI Vendors Handle Essential Training Data for Generative AI

LightBlue

- AI Development (Experienced)

- Annotation

- Data Management/Labeling

- IT/Internet

- Annotation

- Data collection

- Data Management

- Experienced

-

Micro Control Systems: AI “Visualizing” Factories to Enhance Manufacturing

Micro Control Systems

- AI Development (Experienced)

- Annotation

- Data Management/Labeling

- IT/Internet

- Annotation

- Data collection

- Experienced

-

harBest Boosts MiiTel’s AI Speech Recognition

RevComm Inc.

- AI Development (Experienced)

- Annotation

- Data Management/Labeling

- IT/Internet

- Annotation

- Data collection

- Experienced